Automotive

Moulded seals made of LSR and HTV, silicone extrudates and a comprehensive range of cable protection systems/technical textiles

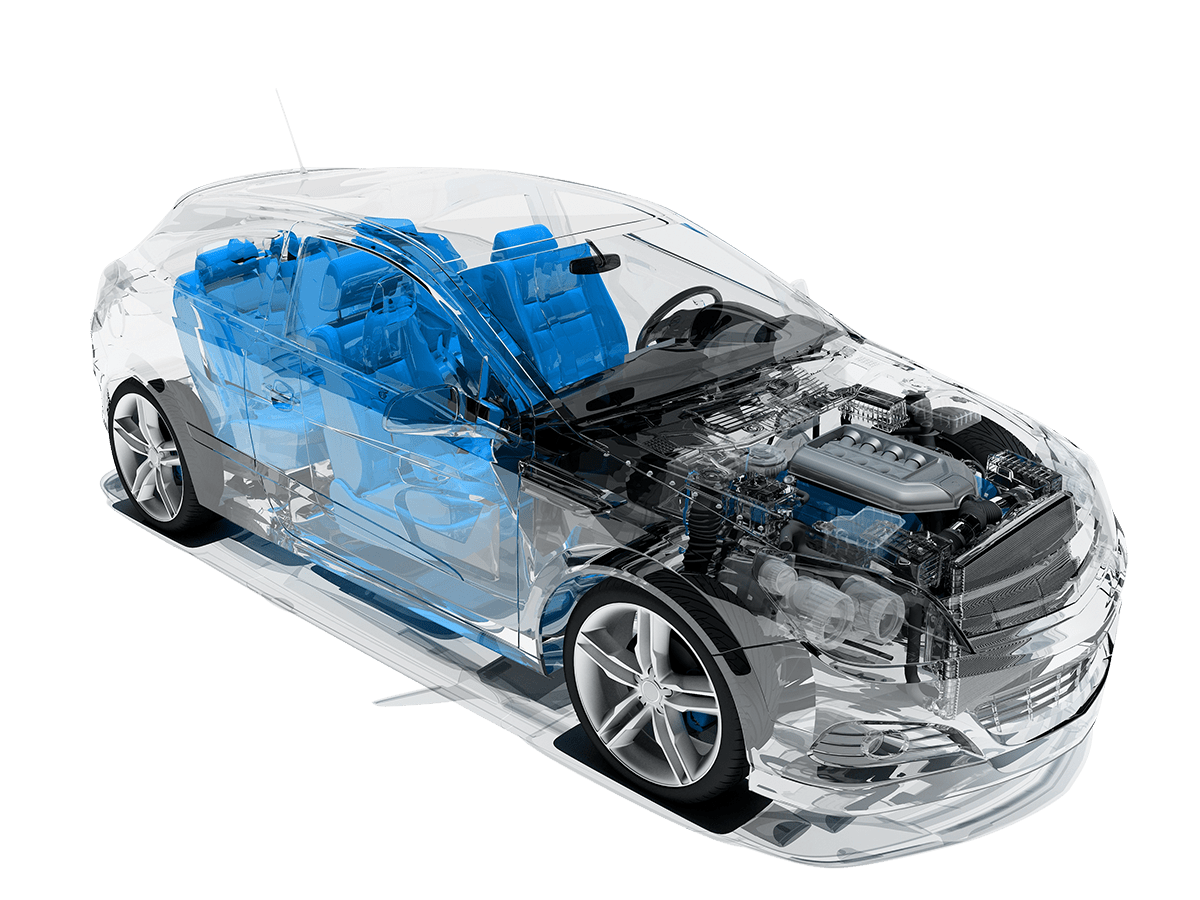

Whether for cars, lorries, buses or caravans, for internal combustion engines, plug-in hybrids or electric vehicles, our moulded seals made of LSR and HTV, our silicone extrudates and cable protection systems as well as technical textiles defy high temperatures and severe stresses. They therefore provide long-term protection for vehicles and people.

The automotive sector places the highest demands on mechanical stability, temperature resistance, noise insulation as well as abrasion and crash resistance: Our sealing, insulation and protection solutions meet these demands. We are certified according to the automotive standard IATF 16949 and meet the requirements and test catalogue according to "Original Equipment Manufacturer" (OEM). For decades, we have been impressing our partners as an OEM, first-tier supplier, component supplier and assembler.

Our fabric-reinforced sleeves, moulded parts and profiles made of silicone, as well as our fabric sleeves, can be found throughout the entire vehicle. They seal plugs, protect flap and controller seals, insulate air-conditioning technology, encase lighting technology and fill airbag generators. Our silicone products can be dyed in all RAL colours and thus adapted precisely to your requirements in terms of appearance. In short: there are virtually no limits to the possible applications of our silicones in the automotive industry.

Application examples

- Electrical wiring systems

- Temperature sensors

- Engine/motor cabling

- Battery cables

- Seat cabling

- Airbags

- Brake lines

- Door locking systems

- Air-conditioning lines

- Sliding roof systems (frame seal)

- Moulded seals

- Lighting systems

- Rainwater drain hoses

- Spark plug connector gaskets

- 2-component parts

- Door and window seals

- Windshield washer systems

- Housing seals

- Impact protection

- Fittings

- Edge protection