BIW HAS A CLEAR PERSPECTIVE

NEW SCOPES OF APPLICATION FOR CRYSTAL CLEAR

MATERIALS IN OPTICAL APPLICATIONS

Processing of optical Liquid Silicone Rubber (LSR) – an alternative to highly transparent thermoplastic and glass

The economic production of complex geometries in the silicone moulding process is well known. Optical liquid silicone types vulcanised to highly transparent elastomers represent new process challenges and alternatives. Optical silicone is an excellent alternative for the industry to glass and highly transparent thermoplastics such as PC or PMMI.

As well as the extremely positive mechanical properties, such as ageing and permanent temperature resistance up to 200 °C, particularly the transmission values and light refraction index are highly significant in the crystal clear application. Optical silicone is furthermore electrically insulated, water repellent and flexible at low temperatures.

LSR crystal clear – a new market potential for various industries.

The scope of application particularly comprises fibre optics for the automotive industry, LED components, Xenon headlights, mobile phone cameras, street lighting and products for sensor technology. Moreover, the production of lenses and other optical elements will be realised with silicone components in the future.

Transparent standard thermoplastic and silicone materials generally tend to become yellow. Chemical processes are the reason for the discoloration. It is the nature of things. During the past years, some silicone manufacturers have addressed this topic in depth and have developed special formulas for these applications.

Advantage: crystal clear material for life, good transmission and light refraction values for optical fields of application.

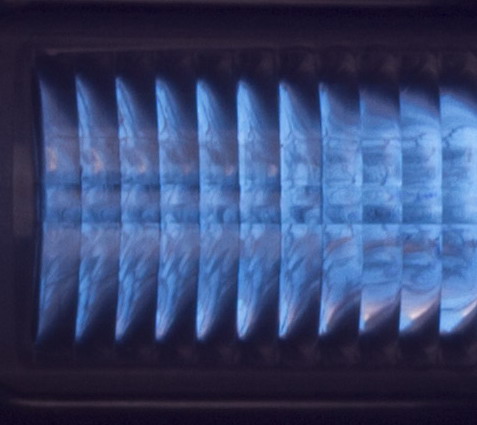

The LSR components available in the market are generally produced in the LSR injection moulding process and are available in A and B component quantities of 20 and 200 kg. The difference from optical silicone is viscosity so that the optical LSR materials are low-viscous at room temperature when delivered - i.e. liquid, like water. This complicates processing and creates particular challenges for the injection moulding process.

Due to the high optical quality requirements for the components, the handling of the article is an important step in the process chain. Automatic extraction devices at the machine facilitate the handling.

The requirements for the optical surfaces demand enormous precision and purity with respect to tools as well as during production. BIW moulding has access to a clean room according to ISO 14644-1 Class 7 for this application.

Please contact us directly if you have questions regarding optical silicone. We are happy to develop the optimal solution also for your project – THAT‘S CRYSTAL CLEAR!