BIW IS INVESTING IN 3D PRINTER

The journey from an initial idea to a prototype is often laborious, and components go through multiple design iterations until problems are resolved that were found during development. This takes time and money.

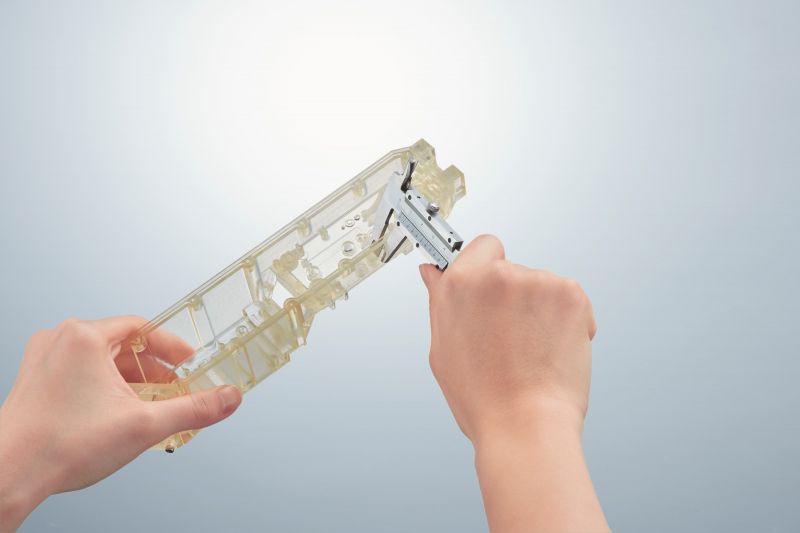

In order to implement ideas faster in the future, BIW has invested in a high-resolution, multi-material 3D printer from Keyence. What’s particularly special about this is the

possibility to print models with silicone acrylate in Shore A hardnesses 35 and 65 in order to obtain a model comparable to the silicone component. As a result, initial prototypes are already quickly and easily produced at the start of new projects, and the design and form of their parts can be evaluated. Assembly and functional problems during later installation are thereby detected at an early stage and there are fewer iteration loops.

We would also be happy to help you find and optimize the design for your parts.