BIW INVESTS IN NEW HCR MACHINERY AND COMPLEMENTS TODAY‘ S RANGE OF MOULDED PARTS

Expansion of the machinery opens up new markets and confirms the growth strategy of the Silicone Mouldings division.

In recent years, the Silicon Moulded Parts division has seen steady growth and, in addition to its focus on LSR processing, is constantly working on new production techniques and opportunities in the field of silicone processing.

New growth markets, new customer profiles and rising quality requirements have inspired us to invest in new technologies and systems to meet market requirements in the long term.

In the meantime, BIW has expanded its machinery to include more than 30 injection moulding machines and presses.

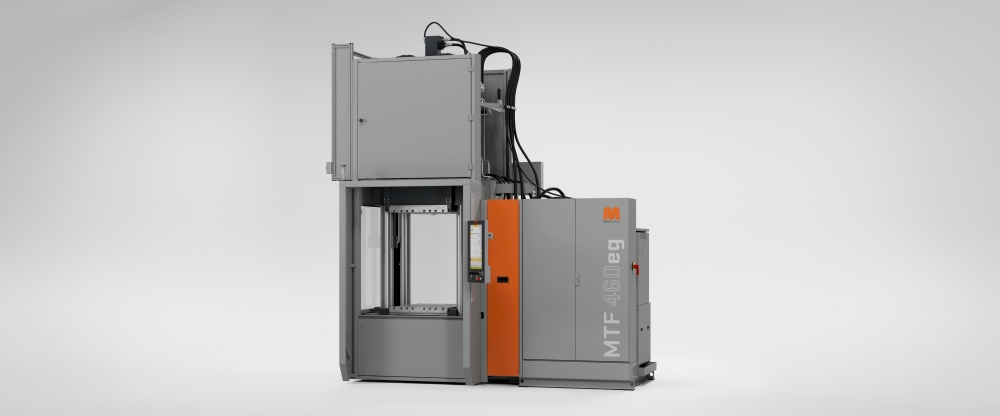

To ensure that BIW always enjoys the latest technical developments, during the second half of 2018 we will install a new plant in the moulded parts division which will differ significantly from today‘s machinery.

Growth – above all in HCR processing for moulded parts and frame production – together with a new project for a key account, means that this field of semi-automatic machines is being complemented in a unique way for BIW.

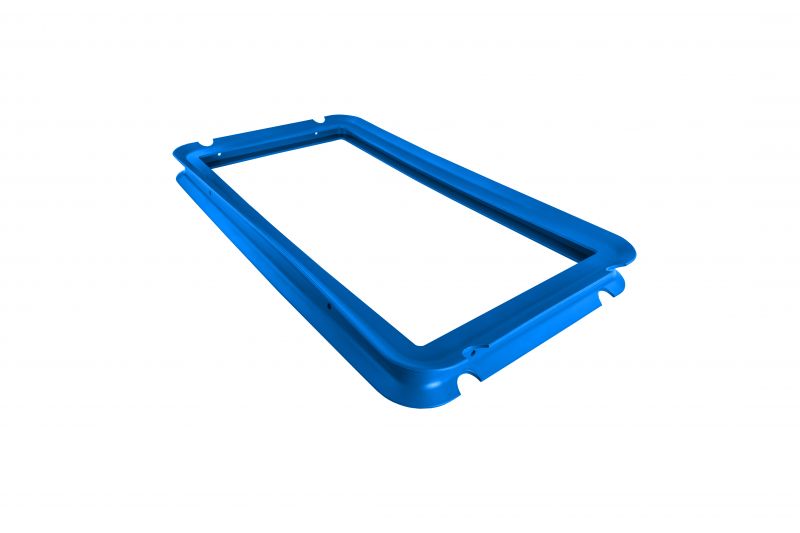

This new machine is suitable for processing heat cured rubber (HCR) using compression moulding AND injection moulding. This investment in the future opens up new possibilities, especially for large-volume items such as large bellows, frames, silicone mats, window seals, moulded hoses, seals for packaging machines and high-voltage applications. Despite today‘s high level of automation in moulded parts, by employing intelligent and simple tooling concepts the plants will also be capable of producing smaller quantities in future.

This new machine is suitable for processing heat cured rubber (HCR) using compression moulding AND injection moulding. This investment in the future opens up new possibilities, especially for large-volume items such as large bellows, frames, silicone mats, window seals, moulded hoses, seals for packaging machines and high-voltage applications. Despite today‘s high level of automation in moulded parts, by employing intelligent and simple tooling concepts the plants will also be capable of producing smaller quantities in future.

The use of HCR, which is produced in-house in our own BIW compounding facility according to defined recipes, offers all options for using special mixtures in a project.

This new machine opens up huge potential for us and our customers. We look forward to your inquiries and ideas for special applications.  The BIW moulded parts competence-CENTER guarantees our customers a sufficient production capacity due to the 3-layer model and five working days of production.

The BIW moulded parts competence-CENTER guarantees our customers a sufficient production capacity due to the 3-layer model and five working days of production.

For you, this means optimum delivery times and an impressive response time. Together with you, the BIW moulded

parts competence-CENTER realises challenging and special projects and advises you to the highest standards both

commercially and technically.

Fast access and short delivery times for moulded parts can also be realised with an optimal logistics concept. Come and talk to us about your projects which may not have been feasible in the past due to the manufacturing constraints. We always have a solution.